What is Economic Order Quantity?

Economic Order Quantity (EOQ) is a formula used in inventory management to determine the optimal quantity of goods to order, taking into account factors such as carrying costs and ordering costs. The objective of EOQ is to minimize total inventory costs while maintaining an adequate level of inventory to meet customer demand.

Table of Content

Economic Order Quality (EOQ) Model

The decision related to order quantity can be stated in the Economic Order Quantity (EOQ) model. This model defines the relationship between the costs of placing orders, inventory carrying costs and the order quantity. EOQ refers to the optimal inventory size to be ordered with the supplier to minimise the total annual inventory cost of the business.

This model is based on the following assumptions:

- The demand rate is constant.

- There is no change in costs.

- There is unlimited production and inventory capacity.

In spite of these restrictive assumptions, the EOQ model is helpful for organisations in making ordering decisions, even under operating situations that deviate from the above-mentioned assumptions. The following is the Total Annual Cost (TAC) equation for the EOQ:

TAC = (A/Q)Cp + (Q/2)CH

Here,

(A/Q)Cp = Annual ordering cost

A = Annual demand for the item

Q = Order quantity

Cp = Cost of order preparation

(Q/2)CH, = Annual inventory carrying cost wherein average inventory is assumed to be half the order quantity Q

CH = Inventory carrying cost per unit per year

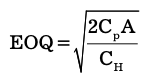

By combining ordering costs and inventory carrying costs, organisations can evaluate the total cost of any given order quantity. The method for determining the minimum-cost order quantity is by using the EOQ formula, which is as follows:

Let us learn to calculate the EOQ using a few examples.

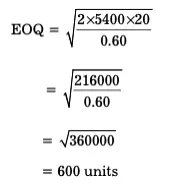

Example: An organisation uses material A uniformly throughout the year. Using the following information, determine the EOQ of material A:

- Annual requirement: 5,400 units

- Ordering cost: ₹20 per order

- Holding cost: ₹0.60 per unit

Solution:

The economic order quantity for material A is 600 units. Apart from determining order quantities, the EOQ formula can also be used to calculate the number of orders to be placed per year, annual ordering cost, annual holding cost and combined annual ordering and holding cost. Let us calculate them as follows:

Number of orders to be placed per year = Annual Demand/EOQ

= 5400/600

= 9 orders per year

Ordering cost = Number or orders per year × Cost per order

= ₹(9 × 20) = ₹180

Holding cost = Average units × Holding cost per unit

= (600/2) × 0.60

= ₹180

Combined ordering and holding cost at Economic Order Quantity (EOQ)= Ordering cost + Holding cost

= ₹(180 + 180)

=₹360

The EOQ is a crucial cash flow tool. The formula can assist a business in controlling the amount of cash held in its inventory balance. Inventory is, aside from human resources, the most valuable asset for many firms and these organisations must keep enough inventory on hand to meet client demands.

Advantages of EOQ

The main advantage of the EOQ model is customer-specific recommendations regarding the most economical quantity per order.

The following are some other advantages of EOQ:

- EOQ offers to buy more quantities with fewer orders to take advantage of bulk purchase discounts and minimise order costs. Alternatively, if the inventory cost is high and the order cost is relatively low, you may want to show more orders for fewer items to minimise the inventory cost.

- For many small businesses, maintaining sufficient inventory to meet customer demand is a balancing act.

- Another advantage of the EOQ model is that it provides specific company-specific numbers for inventory levels, reorders and the number of items to order. This simplifies the replenishment process and improves customer service by making inventory available when needed.

- EOQ enables organisations to manage its inventory in a better way and lessen running expenses and this ultimately leads to higher profits.

- EOQ enables restocking an easy process as the formula assists to evaluate how often should orders be placed.

Limitations of EOQ

Some of the downsides of EOQ are as follows:

- The EOQ requires a slew of assumptions to survive and function

- As per the formula of economic order demand, the consumer demand is stationary in nature and this makes it implausible to compute during seasonal changes.

- Companies that utilise EOQ has to perennially monitor reorder levels as the moment level of raw materials reaches reorder level company has to order goods from suppliers and this is where the company will need to recruit staff who will monitor stock levels which again is a time taking, tedious and expensive process.

- Another disadvantage of EOQ is that it may happen that supplier may not have required raw materials and in case the company needs immediate raw material to fulfil unexpected demand than it can create trouble. Since EOQ system is largely based on the philosophy that demand will be constant which can be anticipated precisely.