Quality management is a comprehensive approach to ensuring that products or services consistently meet or exceed customer expectations. It involves a set of principles, techniques, and tools aimed at improving processes, reducing defects, and enhancing overall quality.

Table of Content

Techniques of Quality Management

There are various approaches for quality management in industries; they vary depending on the needs of the companies, therefore, you will go through some of the most widely used techniques.

Kaizen

According to CIMA Official Terminology, kaizen is a Japanese phrase that refers to continuous improvement in all aspects of an entity’s performance at all levels. Kaizen is a Japanese idea that aims to incorporate all levels of employees by encouraging tiny incremental changes across all aspects of the business that, over time, have a significant influence.

Processes are standardised, assessed and then improved in the manufacturing industry, with the result being less waste and better productivity. In an organisation, the purchase of a new forklift which optimizes two or more production stations or moving some inventory around by the forklift operator to allow for a faster loading and unloading time at a station are the examples of kaizen.

Kanban

Kanban is a method for implementing control and driving improvement that is centred on creating a highly visible working environment. When a quality issue emerges, it is immediately highlighted, highly obvious, and the consequences of the quality flaws are immediately apparent. Because of the high level of visibility, quality faults must be rectified swiftly and permanently. As a result, quality expectations will be met over the Kanban processes’ whole span.

Kanban is frequently used in manufacturing to determine the number of items to create, the rate at which they are manufactured, the manufacturing mix between multiple versions of a product, and so on.

For example, many warehouses place red, yellow, and green floor marking tape on the floor around items that reveals itself when inventory is getting too low. Green colour indicates that inventory levels are adequate; at yellow, production might begin; and at red, levels may have become too low and steps need to be taken to replenish the problem.

In this scenario, the colors themselves are the visual Kanban cues that trigger actions. Kanban requires rigorous control over the levels of materials held in product and raw material storage locations. When maximum stock levels are reached, an order is sent out to halt producing more merchandise. Kanban’s main advantage is that it is a “pull” approach rather than the usual “push” system for process management.

The customer (i.e., the next stage in the process) requires a product or service in the “pull” system. The product or service is subsequently created to meet the demand. The “push” system is an alternative in which a scheduler schedules out activity levels for the following days, weeks and even months, and then items and services are produced according to the plan, regardless of whether or not the process’s consumers require them.

Jidoka

Jidoka is a Japanese phrase that translates to “autonomy.” No, it is not just ‘Automation.’ It is called ‘Autonomy.’ The term “autonomy” refers to “automation with a human touch.” Jidoka is a crucial idea in ‘Lean Manufacturing’ and one of the three pillars of the world-famous ‘Toyota Production System’. Jidoka’s concept is “automatic identification of faults or defects at an early stage, and manufacturing only when the problem has been resolved at its root cause.”

This means that if a fault or flaw is detected, the equipment and operations will immediately halt without any human interaction or oversight. The automatic stop function of modern printing machines when papers get jammed is an example of Jidoka. Printers can detect when there is a problem with its paper supply, stopping the printing process and notifying the user about the error.

Once the paper jam gets cleared, the print resumes while preventing damages to its quality and the printer itself. Saichi Toyoda was the first to adopt this concept in 1896. He originally devised a textile loom that would automatically stop weaving when it came across a faulty thread. This appeared to be beneficial in terms of time, quality and price.

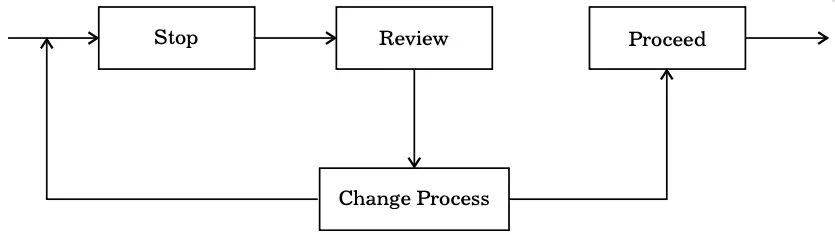

Jidoka is shown in Figure:

Jidoka

- When ‘Jidoka’ or ‘Autonomy’ is implemented, the need for human interaction and supervision to discover and identify defective units or faults is greatly decreased. This is a clear cost-saving, and businesses may put this manpower to better use.

- Production halts when a machine detects a defective product and resumes only when the fundamental cause of the problem has been addressed. First and foremost, this increases the quality of the products, as well as the efficiency of the production system.

- Rather than accumulating faults until the end of the manufacturing line, problems and defects are discovered and

remedied immediately. This saves a significant amount of rework, inspection time, labor time and effort, and aids in the early delivery of items, resulting in cycle time adherence. - Error correction and prevention during the manufacturing process prevents defective units from reaching the consumer, reducing discontent and increasing customer confidence.

Poka-Yoke

Poka-Yoke is a Japanese term that translates to “mistake avoidance.” Shigeo Shingo of Japan invented it in the 1960s of the previous century. He worked as an engineer at the Toyota Motor Corporation. Today, the Toyota production system is still the most effective Poka-Yoke maker and gets near to error-free manufacturing. In industrial engineering, the method is used to prevent and rectify errors throughout the manufacturing process, obviating the need for human quality control afterward.

Poka-Yoke is a method used in Lean Manufacturing and Six Sigma to verify that a production process has as few faults as possible. In Japanese, a ‘poke is an ‘inadvertent error,’ while ‘yokeru’ means ‘prevention’. Processing errors are virtually impossible using Poka-Yoke. It ensures that actions are completed correctly, with no possibility for misunderstandings or human error. It is about taking steps to avoid making any further mistakes. Many of the solutions based on this notion are simple, inexpensive, and effective.

They can be incorporated into the product design or one of the manufacturing processes. Smartphone SIM cards are a nice example. After all, the SIM card can only be inserted in one way into the phone. It is impossible to make a mistake. As a result, it functions as a mistake-proofing device. Digital spell checks are another example of a solution based on this notion.

The Poka-Yoke procedure assists producers in not just removing defects that have already occurred but also in preventing defects from occurring in the first place. This principle has inspired a slew of technological innovations. Only a few examples are control systems, touch techniques, fixed-value methods, motion-steps methods, and sensor devices. Limit switches, touch switches, and proximity switches are some of the most commonly utilised solutions.

5S

5S is an approach for creating a clean, uncluttered, safe, and well-organised workplace to reduce waste and increase productivity. It is intended to aid in the creation of a positive work environment, both physically and mentally. The 5S principle is applicable to any work scenario that benefits from visual control and lean production. The 5S condition of a work environment is pivotal for employees and lays the foundation of first impressions for customers.

The following is the 5S list:

- Seiri/Sort: Distinguishing between essential and non-essential elements

- Seiton/Straighten: Organising the necessary resources in a way that ensures that everything has a home.

- Seiso/Shine: Cleaning the work environment

- Seiketsu/Standardise: Creating a mechanism to keep 5S in check and make it a habit

- Shitsuke/Sustain: Creating a healthy and safe working environment (Safety)

The 5S Principles are widely regarded as efficient techniques for improving workplace organisation, decreasing waste, and enhancing efficiency in a variety of industries. Organisations must be careful not to let the 5S Principles become synonymous with the company’s whole improvement endeavor. Otherwise, instead of being a critical element of a bigger continuous improvement journey, it may become the final aim of your company’s improvement process.

When 5S is part of a bigger program and the entire organisation has adopted its principles, the maximum advantage is gained. 5S is a corporate principle that should be embedded in the company’s culture, not just a system. For example, a company wants to improve its engineering process.

To do things more effectively, the company adopted the 5s principles in the following ways:

- It asked “why” to identify waste and eliminate it (Sort).

- While doing so, it was able to determine an order in which engineering should be done (Set).

- The company implemented the engineering review process to find critical errors and remove the clutter, making it easier to identify errors (Shine).

- The company then wrote down as many of its new processes to improve engineering consistency and efficiency (Standardise).

- To date, DMC has made 5s part of its culture and everyday practices (Sustain).

GEMBA

The term Gemba refers to the “reallocation of labor,” which in manufacturing usually refers to the shop or plant floor. Many manufacturers are familiar with the notion of a Gemba Walk, which involves team members visiting the plant floor to observe processes in action. It is vital to emphasise that the objective of the Gemba walk is not to chastise or disgrace anyone who doesn’t follow the protocol to the letter.

Gemba walks are designed to bring teams closer together and improve processes by locating issues at their root. Understanding and being connected to Gemba are the first steps toward good management. Since you know that Gemba is where everything happens and that you should go there whenever you need to improve or solve a problem,

Some golden rules are following:

- The first action to take when an issue develops is to go to Gemba

- Examine the Gembutsu (“relevant objectives” such as scrap, broken machines or returned goods)

- Take only temporary action

- Determine the source of the problem

- Create a standard to avoid recurrences

For example, the Vice President of the company takes the walk along with the heads of all departments everyday at 10AM.Each stop on thewalk is centred around a production board, and if any discussion at a board lasts longer than 3 minutes, they will assign someone responsible to coordinate a meeting or initiate a review of the issue. Operators at each location participate and provide input when issues arise.

As a result, direct lines of communication have immensely increased as the staff received first-hand communication on a daily basis from the top management about what was going on in the organisation. Moreover, the staff knew that senior management were interested in them and their work. They witnessed their leaders identify problems and take steps to resolve them.

ANDON

A status-display station is referred to as an andon in manufacturing. The title Andon comes from a Japanese phrase that means “traditional paper lantern.” One of the most prominent forms of visual management used in Lean is the Andon. It is a powerful tool because it ensures that the operation runs smoothly and without bottlenecks. An Andon system is a key component of Toyota’s Jidoka quality control process, which was first introduced as part of the Toyota Production System and is now a part of the Lean approach.

Andon draws the operator’s attention to the assembly line to determine the status of the operation and take immediate action. Andon draws the operator’s attention to the assembly line to determine the status of the operation and take immediate action. When irregularities develop in the assembly line, the operator/employee is authorised and informed to pull an andon cord.

Andon Cords and Their Significance

| COLOUR CORD | CONDITION | ACTION |

|---|---|---|

| Green | Production is normal or smooth | Proceeds to next level |

| Yellow | Problem appeared | The operator takes the help of the concerned authority to fix the problem |

| Red | Production was terminated | When a problem has not been found and has to be investigated further |

These three color signals are commonly employed in numerous production domains. Some businesses, on the other hand, prefer to establish color codes that have specific meanings such as white for the end of a production run and blue for a defective unit. A simple example of an andon that we see on a regular basis is a warning light on your car’s dashboard that warns when the petrol tank is about to run out.

Types of Andons

- Manual: Andons are manually activated in the assembly line by the operator or employee:

- Pressing static button

- Pulling a cord

- Pressing static button

- Automatic: When requirements set in the assembly line are not met or are missing, andons are activated automatically on the conveyor.

Benefits of Lean Manufacturing Andon

- Improve transparency: Encourage quick responses to quality, downtime, and safety issues

- Increase productivity: Pay close attention to any difficulties that arise during the manufacturing process

- Strengthen flexibility: Increase operator accountability by giving them more responsibility for good productivity and giving them the authority to intervene when problems arise

- Reduce downtime: Improve supervisors’ and operators’ abilities to detect and handle manufacturing difficulties rapidly

- Save costs and time: Provide a straightforward and consistent method for communicating information on the factory floor

Six Sigma

Six Sigma is a TQM-based process for achieving extremely low defect rates, according to official terminology. The Greek letter sigma denotes standard deviation, so ‘six sigma’ indicates that the error rate is greater than six standard deviations from the mean. To achieve six sigma, a company must have a failure rate of less than 3.4 per million goods. In practice, firms use statistical process control to monitor and chart processes, discovering exceptions to upper and lower bounds and attempting to reduce the number of errors.

You will go over the following seven fundamental Six Sigma principles:

- Always keep the customer in mind

- Gain a better understanding of how work takes place

- Ensure that your procedures run smoothly

- Focus on value rather than waste

- Eliminate variation to prevent defects

- Collaborate with the team to gain buy-in

- Organise your efforts systematically and scientifically

Quality Tools

These seven core tools of quality, first stressed by Kaoru Ishikawa, a professor of engineering at Tokyo University and the father of “quality circles,” have various names among quality professionals. Master these tools to begin your quality journey, and you will have a name for them as well indispensable.

- Cause-and-effect diagram (also called Ishikawa or fishbone diagrams): Many possible explanations for an impact or problem are identified, and ideas are organised into helpful categories.

- Check sheet: A organised, pre-prepared form for gathering and analysing data; a general tool that can be used for several purposes.

- Control chart: A graph that shows how a process evolves. When current data is compared to past control limits, it may be determined whether the process variance is predictable or consistent (in control) (out of control, affected by special causes of variation).

- Histogram: The most typical graph for displaying frequency distributions, or how frequently each particular value in a set of data appears, is the bar graph.

- Pareto chart: A bar graph depicting which elements are more important.

- Scatter diagram: To find a relationship, graphs pairs of numerical data with one variable on each axis.

- Stratification: A technique for sorting data from a multitude of sources and identifying patterns (some lists replace stratification with a flowchart or run chart).